June 2021

The patient was referred by Dr. W. for retrieval of a fractured abutment from an Ankylos CX implant in the #30 site. This implant was placed on 02.25.21 and the restoration was placed on 06.24.21. The case presented with no prior recovery attempts and the crown and abutment screw were still in place. She was expressing concern on several levels. She was experiencing pain around the implant site which she was coping with by moving mastication to the opposite side. Also, she was concerned this had occurred in just over one year of function so the question of “why did this occur” was paramount in her mind. The “why issue” will be address at the end of this report.

Part I. Recovery of the fractured abutment

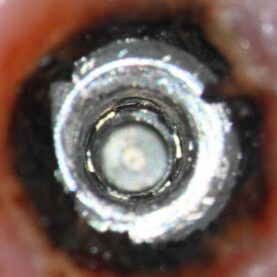

As the crown was still in place and noting from the intake form the abutment was from Atlantis, which like the OEM Ankylos abutments, has a free-floating laser assembled screw as the screw threads at M1.8 are larger than the through bore diameter of the abutment, 1.12mm. Therefore, the easiest way to access the implant top is to cut the head of the abutment screw off which releases the crown. The following preop. photo was taken at this point in the recovery. The photo on the right shows the edentulous space for a greater understanding of the thin fractured abutment cross section relative to the large mesial to distal space. This visually demonstrates the amount of mesial-distal space which translates into a huge amount of applied torsional loading onto the thin fractured cross section.

The abutment recovery was routine with reduction of the abutment screw down 3mm to expose the through bore. Next the through bore was tapped to M1.6mm, the distractor bolt was threaded into place and followed by placement of the distractor nut. The fractured conical portion of the abutment was then distracted and recovered. With microscope guidance, the remaining mobile abutment screw fragment was carefully rotated clear of the implant threads and recovered. The implant was cleaned, and the supplied healing abutment was placed finger tight. There was no visible implant damage when examined at 25x magnification. She was referred back to Dr. W. for treatment planning and future restoration.

Part II. Evaluation of Why this abutment fractured in one year

At the patients request, post clinical appointment and prior to leaving, a detailed conversation was entertained as to why this abutment had failed in such a short time frame. The patient has not needed and therefore has had relatively little dental work to date, so the extraction of #30, implant placement and restoration with failure occurring so quickly, was troubling to her. As I evaluate all the implant abutment fractures in regard to duration in function, location of the fractured component, and the amount of fractured abutment material and type, this case was no exception. While it was no surprise to see another Ankylos abutment fracture on the schedule in a single tooth molar application, the very short time it took to fracture was interesting. The intake form listed this abutment as an Atlantis abutment, but it quickly was apparent this was not the case. The first clue was that tapping progressed rather quickly and while the threads were not deep, a slight eccentricity in the bore allowed for enough thread depth for successful distraction. Once the abutment fragment was recovered, the apical portion of the recovered abutment has a notched geometry as in the top of a castle. This can be appreciated in the above photo of the abutment fragment on the distractor. Ankylos and Atlantis abutments do not have this as the end of their abutments are not notched. This notching is due to a larger diameter through bore which invades the internal wall thickness in the indexing spline areas. While not Ankylos or Atlantis it is consistent for a non-OEM Glidewell abutment and possibly other non-OEM abutments as well. The following photo shows the recovered abutment fragment on the right and an intact Glidewell abutment on the left. Both are on a 1.78mm gage pin which goes completely through the Glidewell abutment and goes into the recovered abutment fragment until it hit a distorted area, secondary to the threading process. The stock Ankylos abutment has a through bore of 1.11mm vs. these at 1.78mm. So, you might say, so what? The problem is the Ankylos abutment has a maximum surface area of just 3.941 mm sq. and is ripe for fracture in this area. For comparison, a Dentsply Astra Tech EV 4.8mm implant and abutment has 9.96 sq.mm. With this Glidewell abutment, the area is reduced to 2.421sq. mm. I have never measured one this small previously. The smallest before this one was the Neodent CM interface, which is a copy of Ankylos for all practical purposes, and also has an enlarged through bore but at 1.51 mm sq. which nets out 3.118 sq.mm. These abutments also break at an accelerated rate. I believe the data is irrefutable. It might be argued this is the circuit breaker in the system to protect against implant fracture. Unfortunately, the analogy is like having a 40-amp circuit with a 5-amp circuit breaker. Almost any load will prematurely shut it down needlessly. She mentioned that a night guard was suggested. While this may help if she bruxes at night if she was able to engage posterior interferences and no anterior guidance, however, it will not protect her from loading secondary to mastication. I did not see an abundance of pathway wear to suggest a significant bruxing habit, nor did I see lateral excursive interferences. The only way I see to improve the stability of this implant / abutment connection is to use a solid abutment. This abutment will get the abutment cross section up to 4.91 mm sq. While this may work for a while, and clearly better than what was in previously, she has to understand two facts. One, I have recovered many fractured solid abutments as well, possibly 20 two-piece Ankylos abutments to one solid in approximately 220 fractured Ankylos abutment cases to date but recovering a solid is significantly more difficult to do without implant damage. Therefore, by restoring with a solid abutment it does not mean fracture is off the table. Unfortunately, I don’t have a better, simpler solution for this situation as the adjacent teeth are in good shape. I have been involved with three similar cases where the patient fractured a solid abutment rather quickly and the only real solution was to replace the implant with one that has a more overall robust mechanical connection such as a 4.8 EV.