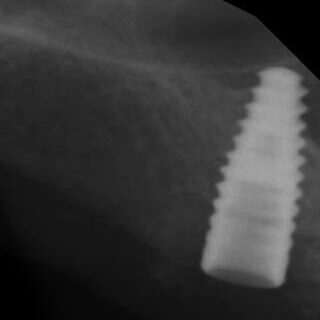

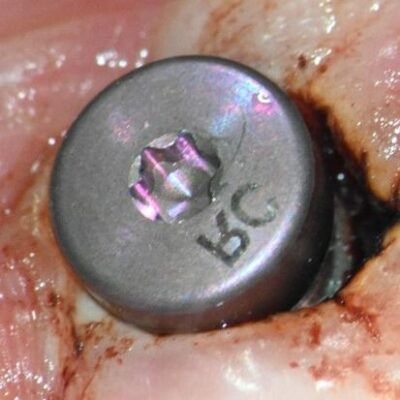

The patient presented for retrieval of a fractured healing abutment screw from a Straumann 4.1 RC BL implant in the #13 site. The healing abutment was under a full maxillary denture when the fracture occurred. The mechanism of failure was thought to be secondary to the healing abutment becoming loose, as there was aged tissue conditioner surrounding the abutment area. Once the healing abutment had loosened, the mastication forces were able to side load the abutment screw and the fracture then occurred through the minor diameter of the screw. There were two prior, unsuccessful attempts to retrieve the fragment. The first was with only hand instruments, but the second did mention the use of a “scaler”. Following a short discussion regarding the retrieval protocol the implant top was exposed with a minor tissue trim of excess tissue. An effort was made to avoid the facial tissue as there was a lack of attached tissue in this area. Once visible, the fragment was found to be nonmobile and the lead thread of the fragment was residing below the first, lead implant thread which makes this case a Type IV presentation in my screw retrieval algorithm. (The complete algorithm is posted on my website mastrovichdental.com) Safe recovery of this fragment requires a concentric, guided drilling approach. Therefore, a precision, custom drill guide was used and secured with Triad gel and sheet resin so the guide would be removable to clean metal debris as the drilling process proceeded while maintaining index to the implant. Once the guide was positioned, a .9mm custom, left hand spot drill was used to establish a start point so the .8mm drill would not drift and to confirm concentricity. However, the starting dimple was not adequately centered and was positioned toward the distal facial. This was still inside the core of the screw but in the event the screw fragment had to be taken out in pieces, it was best to be as concentric as possible. The starting dimple was moved to a more concentric position with a SL ¼ round bur on a high speed handpiece under microscope guidance. A custom left hand .8mm drill was then used and the fragment was drilled completely through. Once bored, a .8mm screw extractor was used to retrieve the fragment without difficulty. A M1.6 x .35 bottoming tap was then passed through the threads to confirm integrity and the supplied healing abutment was placed to 15Ncm. Although there was some minor scarring from the previous recovery attempt it was totally nonconsequential so the prognosis going froward is not changed secondary to this incident or any of the retrieval attempts. CAM

Discussion regarding the use of ultrasonics

There has been much written on the use of ultrasonics in retrieving fractured screw fragments, which I didn’t think a lot about until May of 2023, as it has not been a part of my fractured screw retrieval algorithm. However, I had just recovered fractured abutment screws in two cases where the only reported previous recovery attempts had utilized a limited use of an ultrasonic scaler, yet the amount of implant damage was significant. The clinical findings did not correspond to my understanding as to what destruction an ultrasonic unit might be capable of creating.

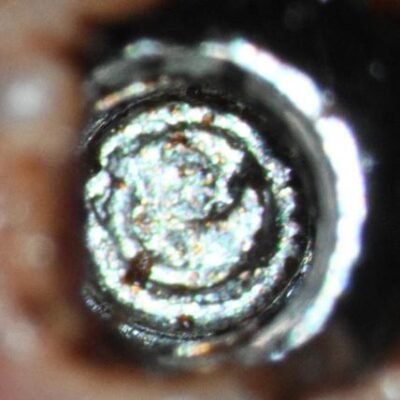

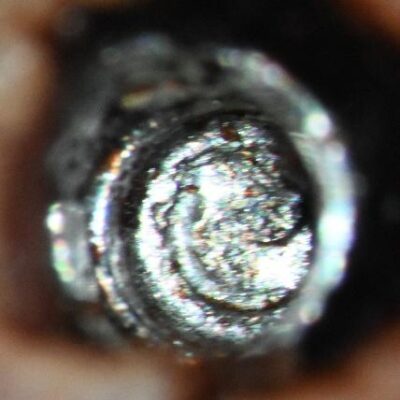

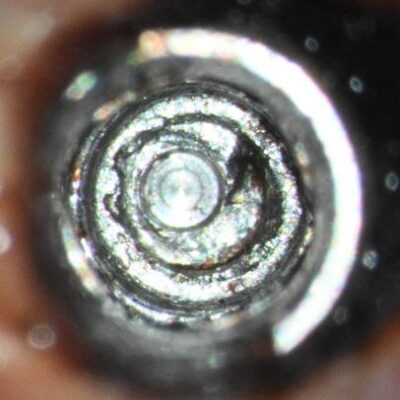

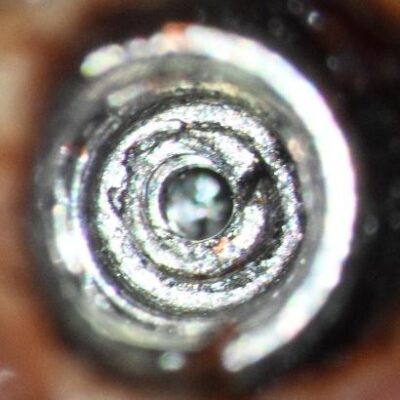

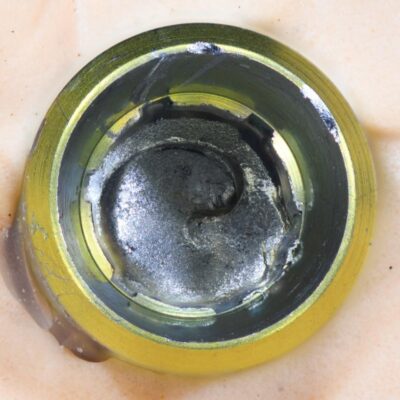

So, I set up a simple trial to see if I could replicate this issue. To create the sample, a cast from a previous case with an Astra EV 4.2 analog in it was used. A new abutment screw was notched using a fine diamond disc in a position so the fracture zone would approximate the top of the implant threads. I then tried to recover the fragment by using a Dentsply cavitron at ¾ power for 2.5 minutes with water irrigation, mostly in a counterclockwise motion. The goal was to retrieve the screw fragment without implant damage. Unfortunately, there was no progress in retrieving the screw fragment, but what I discovered was surprising. The sample was photographed before and after the ultrasonic attempt and displayed below. In only 2.5 minutes, I was well on the way to totally destroying the internal aspect of this titamium analog. Furthermore, with the water spray the process was not controlled with any precision and the ability to hit just the screw fragment was basically impossible. After seeing this pattern of rounded destruction, I now had an understanding of the reason I am referred so many cases with locked screw fragments with this prior treatment history and with this unique rounded pattern of destruction. Therefore, I would highly recommend NOT using an untrasonic technique as a reliable, safe way to retrieve screw fragments. In my experience, a mobile screw fragment is effectively recovered without rotary or ultrasonic instruments. If the screw fragment is non-mobile, a concentric mobilization technique utilizing precision guidance to establish a concentric bore as a way of guiding retrieval instruments, and is much safer to avoid iatrogenic implant damage. In all cases, and for numerous reasons, microscope guidance is my #1 tool. CAM