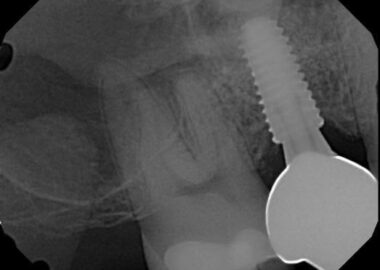

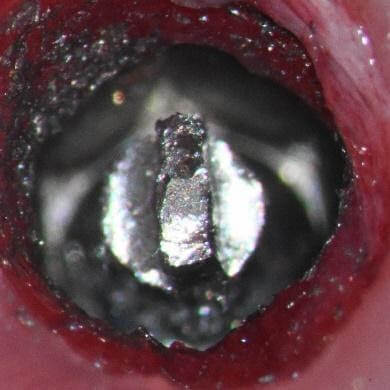

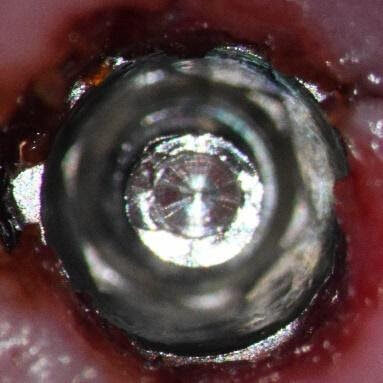

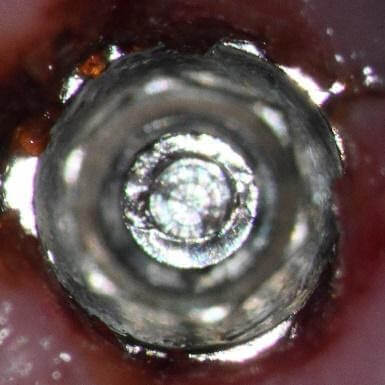

The patient was referred by Dr. S for assistance in retrieving an abutment screw in a Hiossen 4.5 implant in the #3 site. Evidently, the crown was delivered and within a very short time, less than 24 hours, the crown was “loose” so the long journey with this implant began. Multiple prior attempts were made to retrieve this screw by several dentists all of which were unsuccessful. The net result was the drive geometry in the screw head was rounded and the patient was referred here to clear the implant. The normal retrieval protocol was discussed with Eli and his mom and the head of the screw was accessed confirming the loss of geometry in the screw head. Quickly it became apparent a routine slot in the screw head and retrieval would not be sufficient to mobilize this screw. So, the head of the screw was removed along with the crown exposing the head of the implant and the remaining screw shaft which was up well above the implant threads. With this advantage, two small opposing flats were placed into the screw shaft and a custom driver was slotted to fit the existing screw geometry. Twice this was done and both times the applied torque was sufficient to fracture the screw shaft just below the slot. It became apparent this screw was very resistant to retrieval and a total drill out might very well be necessary. At this time, the reason for this event was totally unclear. The questions were why did the abutment become loose in such a short time period, yet the screw could not be retrieved?

The patient was reappointed to return to apply a more aggressive approach.

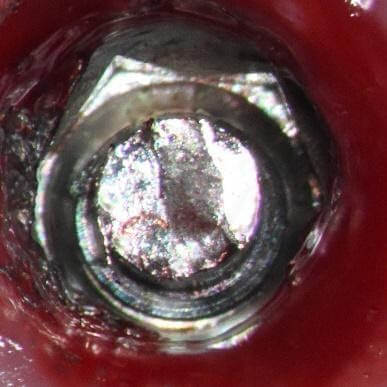

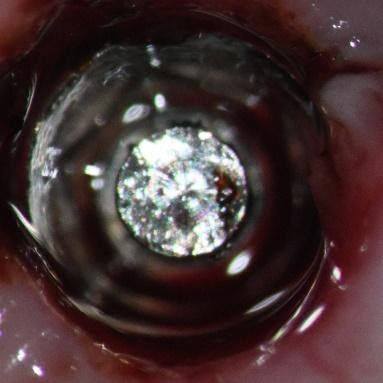

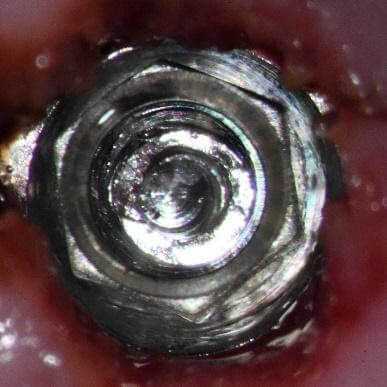

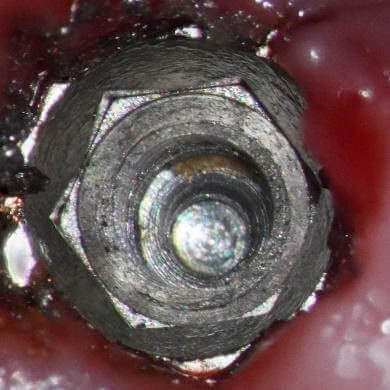

The patient returned for a second appointment to center drill the screw and remove, if possible. If not, then a complete drill out would be indicated. Utilizing custom precision guidance with microscope tracking the screw was spot drilled, and then center drilled with effort to stay concentric on the fragment. The first attempt with the easy out screw extractor was not positive so the first two mm of the screw, which was above the implant threads, was enlarged to 1mm. The extractor was then re-engaged successfully, and the screw was delivered. The amount of torque required to achieve success was not measured but it was significant. Enough to split the screw shaft in the section above the implant threads. The implant was not damaged by any of the retrieval efforts so the prognosis going forward should not be altered.

So why did this happen? I truly no not know at this time. However, I have eliminated many of the theories.

Was it the incorrect screw? I measured the screw fragment on my 14” optical comparator and it measured to be a M2x.4 screw. Correct for this implant. That eliminates the possibility of an undersized screw, with a different thread pitch, cross threading more and more as it progresses into the implant threads. I don’t believe the abutment was seated cross hex and hence the reason for the early looseness, as there was no indication of hex damage on the abutment or in the implant. I also do not believe the correct screw was cross threaded which prevented total screw seating as there was no damage to the implant threads and the screw was delivered too deep into the implant not to see this. The only explanation I have is that the screw never really secured the abutment tightly even though the screw was torqued with the prescribed applied torque not being able to thread through an obstruction in the threads and establish preload on the screw. The abutment would have just walked out of the hex early after delivery. That would mean the screw threads hit something which prevented the head of the screw from engaging the screw head seat. If that was so, then that would explain why the screw could not be moved even though the abutment was loose with no preload on the screw. After removing the screw fragment, I was able to easily pass a tap through the implant threads, so nothing was found there. Possibly the obstruction was in the screw threads which then cleared with the screw fragment retrieval? I do know this was a very difficult retrieval bordering on a complete drill out, so something was preventing the normal rotation in the threads. If it wasn’t a parts misfit, then it must have been debris of some kind. I simply do not have a third possibility at this time.