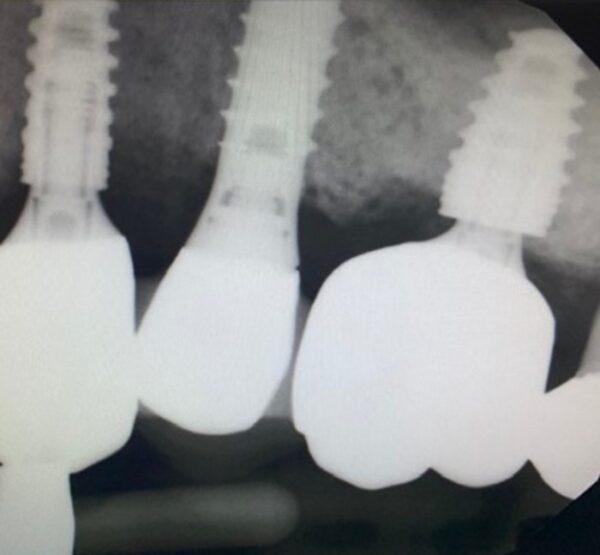

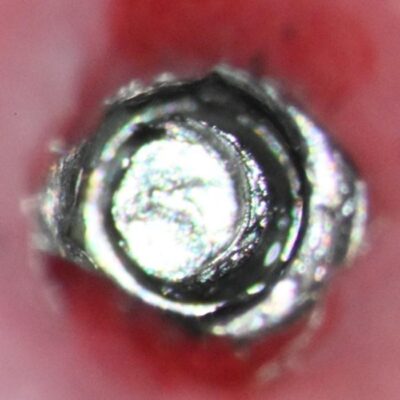

The patient presented upon referral from his periodontist for retrieval of a fractured abutment from a Neodent CM 5×8 implant in the #14 site. There was a prior retrieval attempt by another dentist in the periodontal office, but the fractured abutment could not be recovered. The case presented with an access hole to access the abutment screw through the existing crown with the crown very mobile and being held in place with just the screw. After explaining the recovery steps for this situation, the screw head was accessed in preparation to cut the screw head off as this is the first retrieval step. With the crown recovered, the abutment screw was rotated up as high as possible and then cut off at the level of the abutment fracture. The screw was then allowed to go down and the shaft of the screw was shortened to create 3mm of throughbore space in the retained abutment fragment. The abutment fragment was then tapped to M1.8 and a custom distraction bolt was inserted, and a distraction nut was tightened which released the abutment fragment. The remaining portion of the abutment screw was then retrieved, the implant was cleaned, and the supplied healing abutment was placed finger tight. There was no visible implant damage as view at 25x from either the fractured abutment or any of the retrieval efforts so the prognosis going forward is unchanged.

Mechanical Evaluation

The Neodent CM implant is basically a copy of the Ankylos implant in regard to the conical interface dimensions. However, there is a notable difference in the throughbore diameter and the resulting abutment wall thickness. Specifically, the Ankylos CX implant has a 2.5mm OD diameter as it exits the implant top and has a throughbore diameter of 1.18mm. Simple math yields a titanium cross-section of 3.97 sq. mm. This Neodent CM implant also has a 2.5mm abutment exit diameter but this recovered throughbore measured out on my optical comparator at 1.5mm. Again, applying the math, the titanium cross-section would be 3.143 sq. mm. (This is almost identical to the Bicon 2mm solid abutment.) However, in this case, the abutment fractured just below the implant top. Measuring the actual fracture zone on the recovered crown on the optical comparator the story became worse. The OD of the abutment at the fracture site was 2.438mm with a throughbore diameter of 1.5mm which calculates to 2.9 sq. mm of titanium on the fractured site. This is the lowest number I have seen to date on any of the fractured abutments I have recovered and evaluated, with the possible exception of some TiBase abutments. This absolutely explains why the fracture occurred in the Neodent CM single molar application if titanium cross-section dimension correlate with fractures. I absolutely believe it does, so I would expect them to occur as frequently or possibly more frequently than in the Ankylos system, and that is hard to believe, as I have seen over 200 Ankylos abutment fracture cases to date. This also explains why the Neodent GM line was created which has a larger diameter conical connection (3mm), although the same connection is still used in all implant diameters. To give you some perspective on the numbers here is a partial list of some of my abutment cross-section data at implant top where these fractures have occurred:

Bicon solid abutment-2mm well

Ankylos Cx

Ankylos solid abutment

Straumann RC

3.14 sq. mm

3.97 sq. mm

4.95 sq. mm

6.11 sq. mm

It seems that around 7 sq. mm in the abutment cross-section the fracture rate drops significantly.

As an example, Dentsply EV 4.2 has 7 sq. mm, 4.8 has 9.96 sq. mm, and the 5.4 has 13.38 sq. mm. Done of which I have seen an abutment fracture in, as of yet. Time will tell based on load cycles though. I have recovered 2 fractured solid abutments on Straumann TL WN implants, both were at 12 years of function and in maxillary single tooth molar applications. This fracture zone was 9.51 sq. mm. However, I believe both of these cases are way out on the bell curve. 02-09-2022 Dr. Charles A. Mastrovich