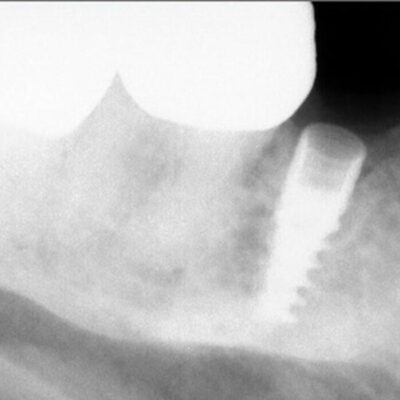

The patient presented on referral form Dr. S. for retrieval of a fractured abutment screw from a Noble Active 3.5 implant in the #29 site. According to the patient, this was the second failure when this implant crown delivery was attempted. Although the specific issues with the first attempt remain unclear, the patient reported, “the crown was loose from the start”, so the restoration was replaced. The current abutment screw fracture occurred during the second crown delivery attempt. Dr. S. reported the abutment screw was torqued to 35Ncm and then the screw “was turned one more time to make sure it was tight”. The screw fracture occurred at that time. There was no prior attempt to recover the screw fragment.

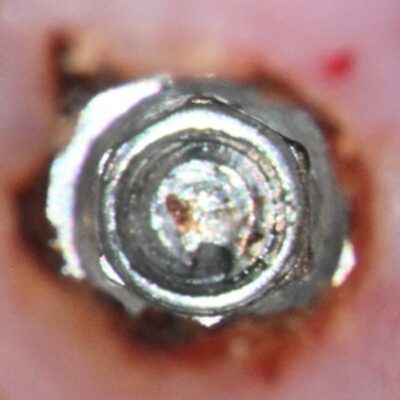

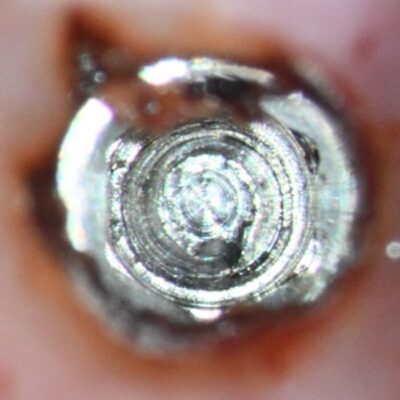

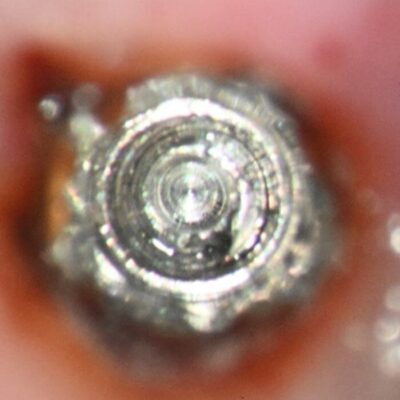

The retained abutment screw fragment top was residing just above the first implant thread, seen in the above photo at 5:00 o’clock. The fragment was not mobile with either an endodontic explorer or modified endodontic spoon. Therefore, this was a Type II case in my abutment screw retrieval algorithm. To safely recover this screw fragment, a concentric mobilization technique is indicated as the amount of mobilization necessary, translated into increasing amounts of screw fragment destruction, cannot be determined at this point. If a total drill out becomes necessary, it becomes increasingly critical to be concentric to avoid implant thread damage. A precision custom drill guide, specifically for the Nobel Conical 3.5 interface, was placed and stabilized with Triad gel resin. This is used to ensure the guide system was stable using the adjacent teeth but was removable so the recovery progress could be monitored microscopically as it progressed. Following spot drilling to establish concentricity for the drilling process, the fragment was drilled completely through at .8mm using a custom left-hand drill made specifically for the guide system. The .8mm diameter drill is used as the core of this M1.6 screw is 1.25mm. This allows some remaining wall strength in the screw fragment core to resist expansion from the wedging action of the screw extractor.

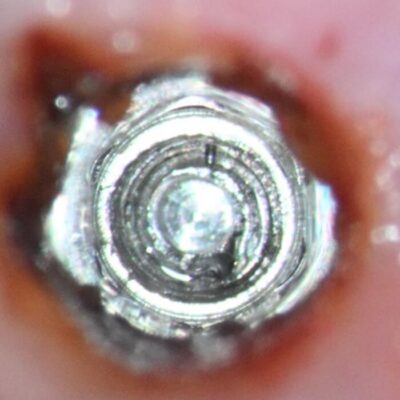

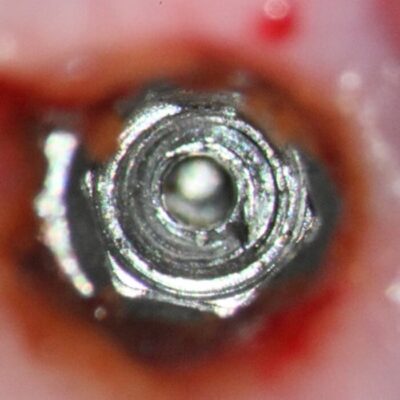

Following drilling though the fragment at .8mm, the fragment was then mobilized and recovered with a .8mm screw extractor.

The implant threads were then cleaned with a M1.6 tap starting with a plug tap and progressing to a bottoming tap. Initially there was some resistance to the tapping process but as the threads were cleaned the resistance dissipated and the tap freely ran through them. As the threads on the supplied healing abutment were significantly distorted, it was not used, and a silicone plug was placed to maintain tissue contours. The case was then referred back to Dr. S. for completion of the restorative process.

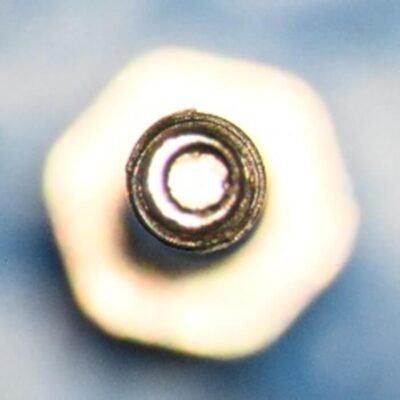

Note, in the end view, the bore is visibility eccentric to the right. While still in the core of the screw, away from the threads, it does illustrate how critical it is to achieve starting concentricity. I believe this error started because there was a slight eccentric spot to guide the .8mm drill. However, there are several reasons the bore will not be concentric: 1. The drill guide is not machined concentric 2. The guide does not fit the implant interface with precision to hold concentricity. Additionally, some interfaces are basically unstable, and it is difficult to achieve a stable, concentric guide. 3. The tolerance between the guide and the drill does not hold the drill concentric. 4. The drill wanders when it starts, as a good spot was not achieved. 5. The drill flexes and wanders, as the smaller the drill diameter the greater will be the drill flexibility. This is a major reason for drill fracture as the drill becomes increasingly sideloaded.

So, what actually happened to precipitate this delivery failure?

Although no exact mechanism of failure was determined, clearly the first attempt at delivery with the immediately loose crown points to a problem with the delivery and a failure of the abutment interface to fully engage the implant and attain proper preload on the abutment screw. As the threads on the supplied healing abutment were incredibly worn and distorted, it is also possible the implant threads were distorted prior to the first delivery attempt, and this was the reason the first abutment screw could not achieve adequate preload. In the second attempt the same problem would still exist, and when the additional torque above 35Ncm was applied, the screw hitting a distorted thread would convert total torque into 100% thread torque contributing to screw fracture in the weaker minor diameter of the screw. This mechanism seems realistic as the taps did engage some thread distortion and had to progressively work through it to clean it up.