The patient was referred by Dr. P. and Dr. L. for retrieval of a fractured abutment screw in a Straumann 4.1 BL implant in the #15 site. This implant had been in function since 2015. The abutment screw fractured on initial placement when Dr. L. applied additional torque to the screw when the crown still felt loose after the initial placement. This abutment and crown combination was manufactured by G. Labs as this new restoration was replacing an existing crown and abutment which reportedly had an open contact issue. The original crown had been manufactured by G.Labs so there was a warrantee issue involved, which pushed the decision to have G.Labs remanufacture the case. Initially after the fracture, the patient was referred to Dr. P., a periodontist in San Diego, for retrieval help. The patient reported that after approximately 1.5 hours without success, Dr. P. decided to abandon the effort and refer the patient here.

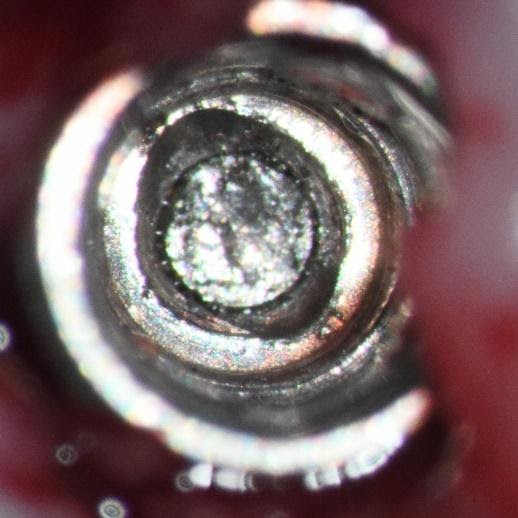

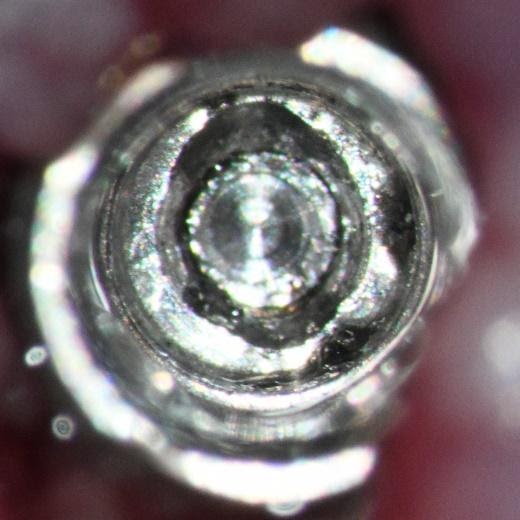

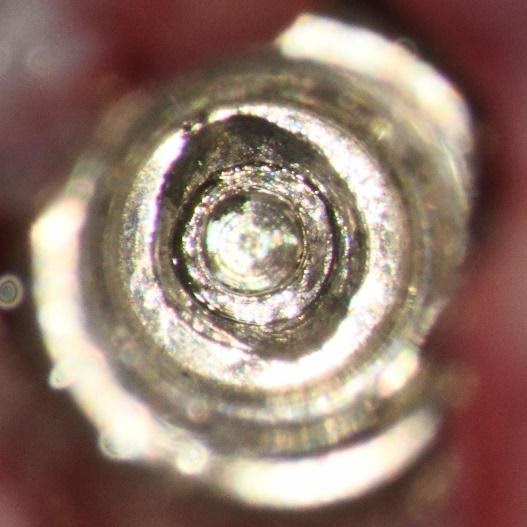

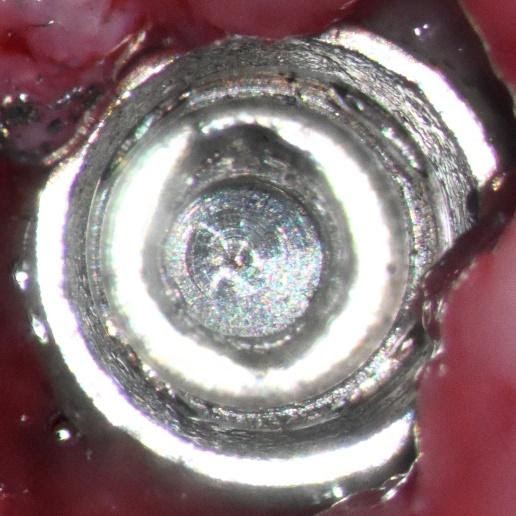

Following a detailed discussion of the retrieval algorithm, the site was infiltrated, and a conservative exposure was made of the implant top, avoiding the existing sutures from the prior recent flap procedure. The initial preoperative photo shows the extent of the previous effort, where a slot strategy was attempted into the top of the screw fragment but also into the top aspect of implant adjacent to the start of the implant threads. This screw fragment was residing slightly below the first implant thread and was non-mobile so in my treatment algorithm it was classified as a Type IV case which required a concentric mobilization technique. The center of the screw fragment was identified and spotted with a custom prototype guide and specific custom spotting drill and modified until it was concentric enough to safely proceed with the actual drilling. The drilling protocol was initiated at .8mm and was taken completely through the fragment. A modified ratchet drive easy-out type screw extractor was then engaged and with considerable force the fragment was delivered intact. A M1.6 tap was chased through the treads to ensure continuity and a Straumann healing abutment was placed finger tight. The patient was referred back to Dr. L. to continue with the restorative phase. Even though there was prior damage to the implant from the original recovery effort, going forward, the prognosis for this implant remains unchanged secondary to this event or recovery efforts as the damage occurred in essentially a non-critical area between the critical top indexing and the lower threaded areas. The patient was very pleased with the successful outcome.

So why did this screw fail? Examination of the crown lead to the answer. The initial clue was the looseness that was felt after initial torqueing. As the crown was present at this appointment, it was tried onto an RC analog and found to be very loose fitting even though the custom prototype RC drill guide fit the implant very well, confirming the RC implant interface. However, when tried onto an NC analog it fit with precision. Obviously, this was an error with the wrong size abutment interface. As both NC and RC platforms utilize the same M1.6 diameter screw, it is possible to thread in an NC screw into an RC implant. Unfortunately, that’s where the compatibility ends. The NC platform has a smaller crossfit connection and the NC abutment screw actually bottoms out before the head of the screw engages the screw seat. This allows all of the total torque placed on the screw to become thread torque with none bleeding off in the screw head seat. The screw fragment is essentially driven and wedged into the bottom of the implant wedging between the bottom and the last implant thread at full torque before fracture. This is why retrieving a fragment like this one often results in having to recover the screw fragment in pieces depending on the amount of torque the recovery tools can deliver. We were definitely fortunate to recover this fragment in one piece, but we were also prepared to proceed to a total drill out with the protocol we were following.