August 2025

This case is presented to illustrate how a case can be set up for mechanical failure when an implant is placed in a position which forces a mechanically compromising restorative solution, creating significant off axis loading forces on restorative components. While there was not a CBCT scan available to understand the bone bed architecture, intuitively, discovering the implant angulation from the lingual toward the facial in the maxilla was an unexpected finding. This case also illustrates how a PA image only shows one plane. In this case, a significant angulation issue was totally undiscoverable, creating more speculation when searching for the abutment screw head after starting from the anticipated normal location.

The patient presented for recovery of a loose cement retained abutment and crown from a Straumann 4.8 RC implant in the #14 site. This implant was placed on 11.11.2016, with the original restoration placed following the initial osseointegration. The abutment was a Straumann custom abutment, as evidenced by the Straumann double bar logo laser engraved on the recovered abutment. The crown was delivered cement retained, as the implant was placed with a lingual orientation making screw retention difficult. When her restorative dentist retired, her new dentist noticed looseness associated with the #14 crown when delivering a new crown on #15. When attempting to access the abutment screw, the screw head could not be located. The patient was then referred to my practice in the hope that the screw could be located, with microscope assistance, enabling the abutment screw to be changed and the restoration preserved.

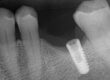

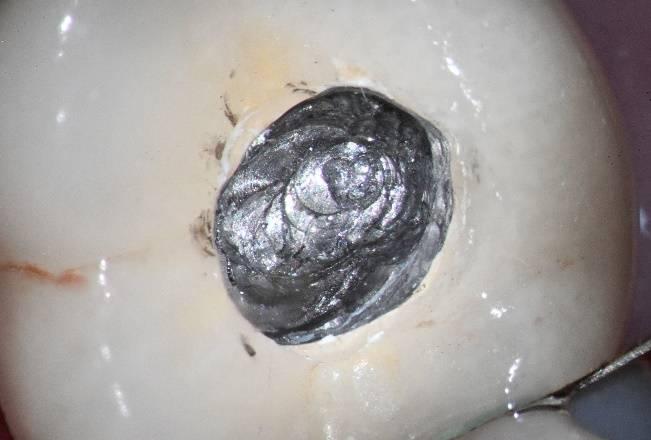

The PA image showed the implant well placed mesial-distally. The preop clinical microscope image showed the initial access opening progressing on a trajectory consistent with the radiograph.

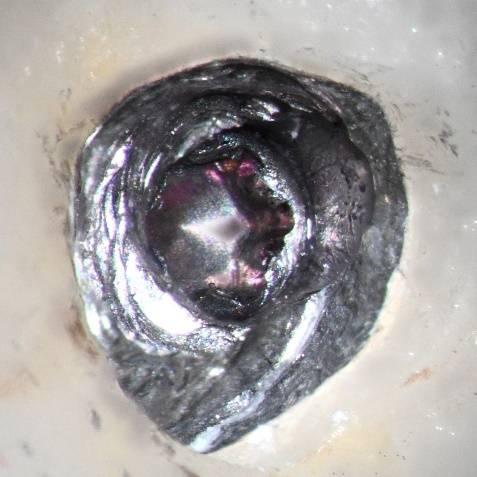

The access opening was deepened and moved in the lingual direction, acting on a hunch the implant was angulated in that direction. Following this path led into the screw access and eventually the screw head was located. With the abutment and crown recovered, the implant was cleaned and examined and found to be intact at the 25x level of inspection. An open tray pickup was placed and photographed to better appreciate the degree of implant angulation.

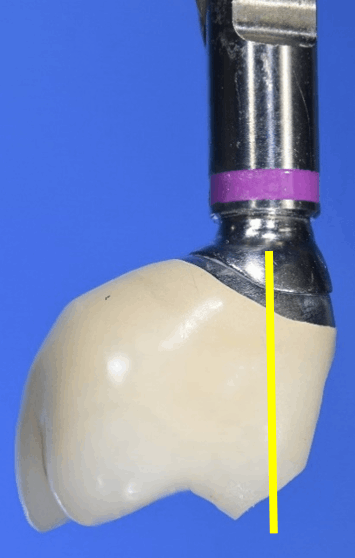

An RC transfer pickup was placed to better appreciate the degree of off axis implant angulation.

Post opertively, the restoration was placed on an RC analog and photographed to assist in the future restorative planning. As a titanium healing abutment was not provided, a silicone plug was placed for tempory tissue control.

Considering many patient factors, replacement of the implant was not an option for her. With that limitation, the future dilemma then centered on the replacement restorative design. While a cement protocol can be repeated, another abutment screw issue will force the loss of another restoration and the process will repeat. With the severity of the implant angulation, the normal occlusal loading will magnify, with significant off axis or torsional loading. Possibly incorporating a design to access the abutment screw from the lingual might allow future access to it. Recently, Straumann has launched a new angulated screw (AS) design option which can be used with their custom milled abutments from Straumann AXS. This is a huge improvement for AXS and allows for up to 25 degrees of angle correction. It does require a unique driver to properly engage the AS screw.

For additional information regarding these procedures, there are additional case studies posted on our website.

Charlie Mastrovich, DDS