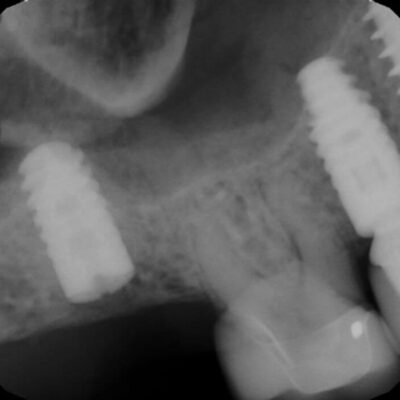

The patient presented on referral from his general dentist with a fractured Ankylos abutment in the #2 site. This is a non-indexed implant (pre-C/X) which the patient reports to have had in function for approximately 6 years prior to the fracture. He presented with the crown and abutment which had the abutment screw shaft intact, which means the abutment fractured and then the laser weld at the thread basket, the most favorable situation with an Ankylos abutment fracture.

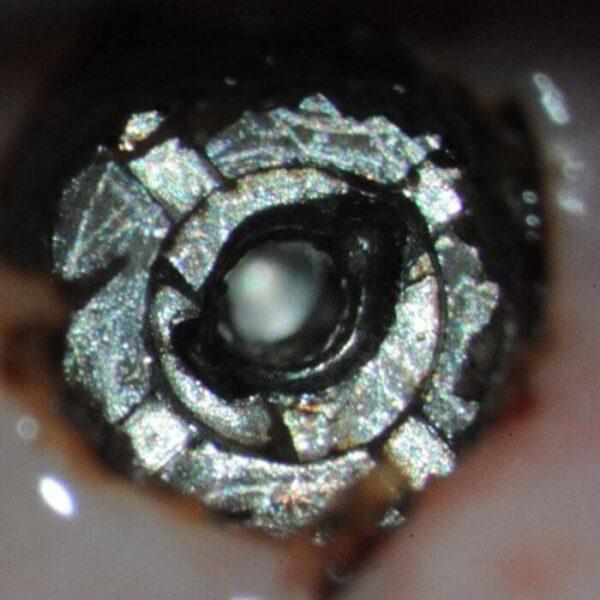

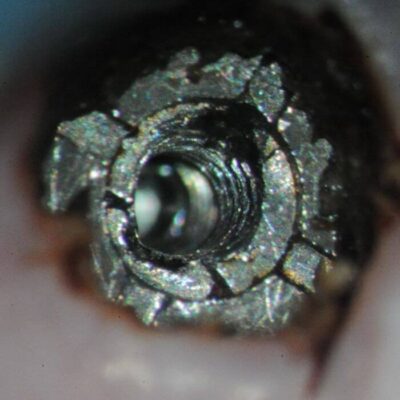

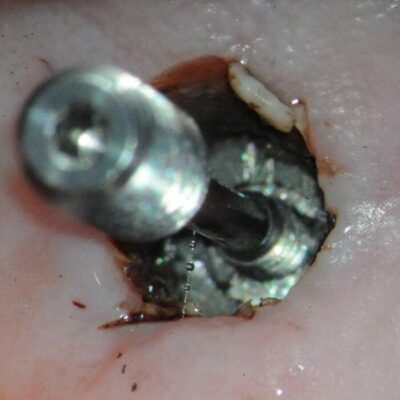

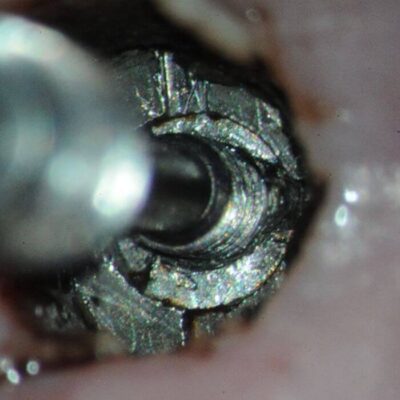

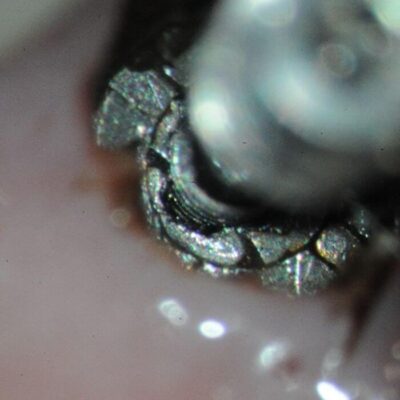

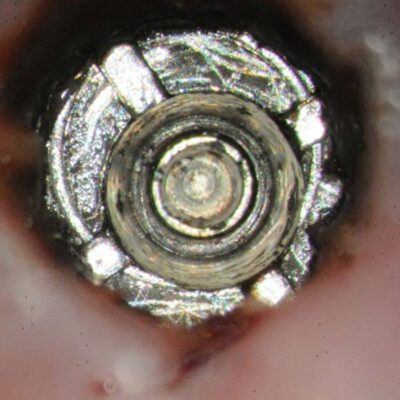

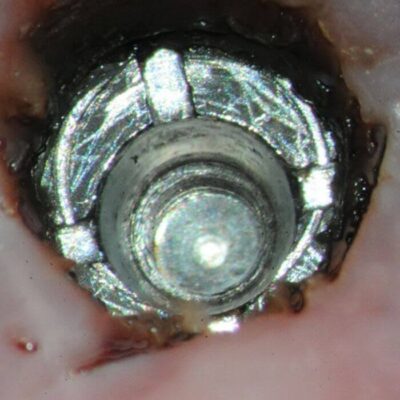

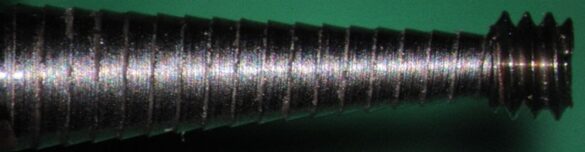

The recovery procedure was explained to the patient and the implant top was exposed by removing some overgrown tissue. In the preop photograph there is clear evidence of a prior recovery attempt with some notching of the conus fragment at the 2 and 8 o’clock positions. There wasn’t any invasion into the implant conus but with the widening of the through bore it becomes more difficult to tap the conus fragment for the distraction technique. With that understood, the through bore was widened to 1.25mm, as that is the predrill size for a M1.6 tap. The Ankylos tap, modified for use on a Bien Air handpiece, was used at low torque and auto reverse mode, essentially peck tapping until the threads were well established. The tap was then changed to a modified plug tap which allowed for a couple of extra full diameter threads to compensate for the loss of some of the through bore wall. The stock Ankylos M1.6 distraction bolt was placed, and the conus fragment was pulled out with a very audible “pop”. The thread basket was then quickly recovered with the Ankylos red stripe tool, and the implant was cleaned. An Ankylos healing abutment was placed and the patient was dismissed to return to his dentist for re-restorative care.

Before leaving I did discuss the etiology issues of abutment fractures and suggested he discuss this with his general dentist before proceeding. The only possible way to decrease the torsional loading on this abutment is to limit the size of the crown and make sure the occlusion is appropriately adjusted.

07-26-2018 Dr. Charles A. Mastrovich