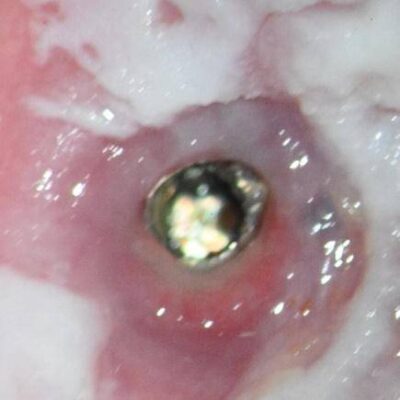

The patient presented on referral for retrieval of a fractured abutment and abutment screw from a BlueSkyBio 4.3 Max implant in the #30 site. The implant was placed on 02.12.2019 and restored on 06.24.2020. The fracture occurred in March of 2023. The case was restored with a Sirona TiBase abutment and a Cerec Emax crown. When the patient recently presented with the fractured abutment the referring Dr. could not retrieve either the retained abutment fragment or screw, so the patient was referred to our practice. When a case presents with both a fractured abutment and abutment screw it is generally easier to recover the abutment fragment first and then the screw as there is better access for the screw retrieval. With an open through bore that is the case here, so the abutment fragment was retrieved with a modified “easy-out” type screw extractor. Next, the screw fragment was evaluated and found to be mobile and residing slightly above the first implant thread, so it was a Type I case in my screw recovery algorithm. Under microscope guidance, the screw fragment was delivered with just an endodontic explorer and a modified endodontic spoon. The implant was cleaned and examined to be free of visual defects at the 25x level of visual inspection. The patient was dismissed to return to Dr. Chan for restoration of the case. Prior to leaving a discussion was entertained regarding abutment types and the suggestion was made to consider avoiding another TiBase designed abutment and instead opting for a Custom Base abutment which will have a more robust titanium cross section above the implant top.

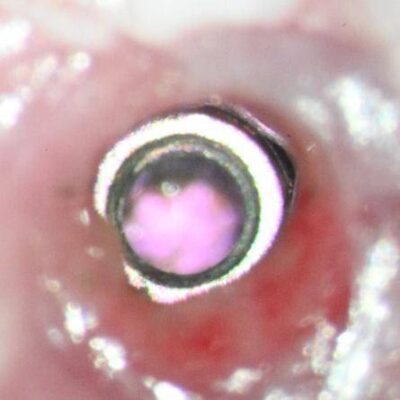

So why did this case fail in such a short period of time? I can account for a couple of reasons which may have acted together. First, this implant connection is a clone of the Nobel Conical 3.5 NP connection. Nobel only uses it in their 3.5 implant. They have a larger connection in their 4.3 and 5.0 conical implants, the RP connection. BlueSkyBio in the Max NP line ports the same NP connection in all diameters of the Max NP line. Therefore, this 4.3mm implant has a connection originally designed for a 3.5mm implant. Routinely, I measure the area of the abutment fracture zone to better understand the mechanism of failure and the dimensions are added to a spreadsheet for comparison. This fracture area measured 4.2 sq.mm. To put that into perspective, the Ankylos two piece abutment has an area of 3.97sq.mm at the same critical area at the implant top. The Ankylos solid abutment has 4.95sq.mm. as there is no though bore. To date, I have recovered over 230 fractured Ankylos abutments and I have recovered about 20 two piece abutments to 1 solid. I also have recovered many Straumann RC fractured abutments which have 6.11 sq.mm in this same fracture zone. As I would expect, there have been significantly less Straumann RC abutment fractures than Ankylos but sadly enough there are more than you might think. Secondly, in a TiBase abutment, as in this Sirona TiBase, the cylinder wall is thin and is especially vulnerable to fracture at the junction of the base shoulder and the vertical cylinder. However, in this case the fracture extended well below the implant top into the conical connection. It seems reasonable to hypothesize the fracture started to propagate in the thinnest cross section and extended from there. I’m not yet clear if the thinnest area is at the cylinder wall or deeper into the conical area but logically it seems like the fracture started first at the cylinder base junction and traversed lower through the conical area. Hopefully that is the case, as changing to a Custom Base abutment will eliminate the thin wall at the TiBase cylinder and shoulder but will do nothing to help the conical wall thickness as that is a limitation of the 3.5mm connection design and one of the draw backs from porting a smaller connection into a larger diameter implant.