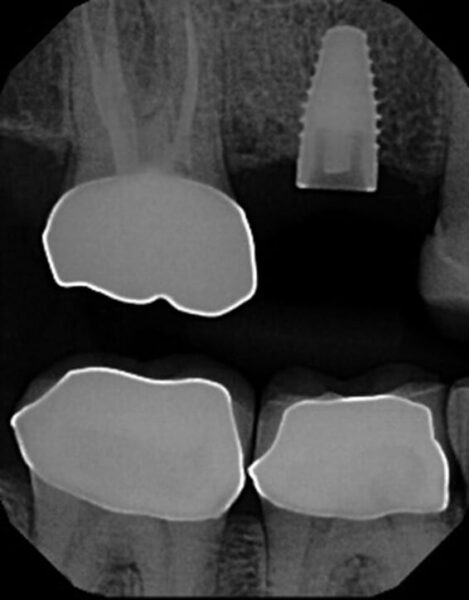

The case involves a failed abutment screw in a Nobel conical 4.3 implant in the #3 site. This case had been implanted and restored by a previous office and per the patient’s history, the implant was in function for somewhere between 2-3 years. The left preoperative radiograph below suggested this implant has a conical interface but restored with a trilobe abutment, a restorative mistake seen in this office more than once. The right radiograph below shows the abutment screw fractured well above the implant threads well into the conical interface.

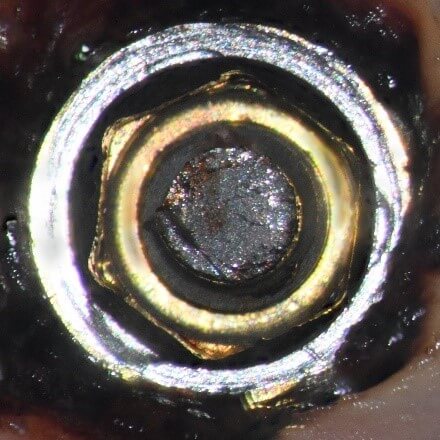

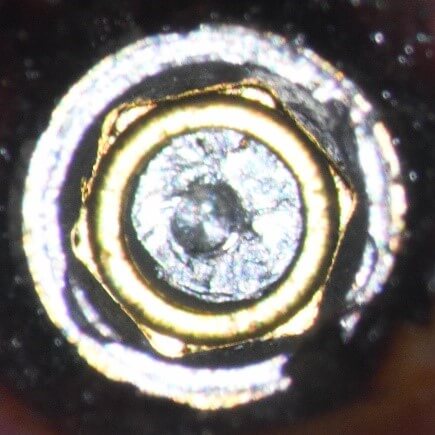

After exposing the implant top, by conservative removal of excess tissue, the screw fragment was found to be non-mobile. So, in my classification algorithm, this is a Type II case forcing mobilization of the fragment to clear the implant.

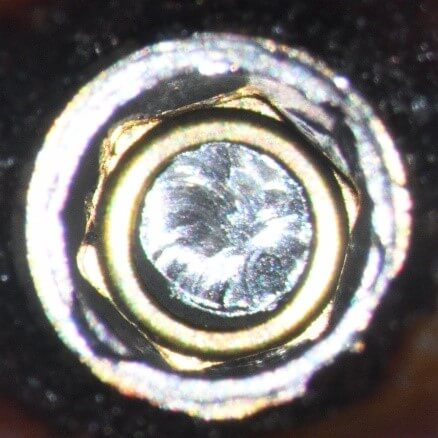

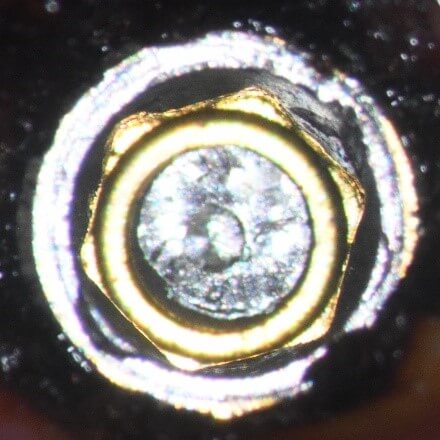

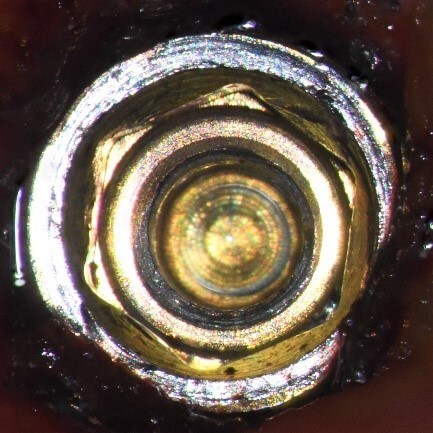

To allow the utilization of a precision drill guide, the excess screw fragment had to be reduced enough to allow unencumbered seating of the drill guide. Next, the fragment was center drilled and a .8mm drill was used to drill to the depth of approximately 2.5mm. This hole was enlarged to 1mm in the top .5mm to allow the start of a .8mm “easy-out” type tool. Using a torque wrench set to a ratchet position, the fragment was backed out without issue. The implant was confirmed clear and without internal damage which would change the long-term prognosis of the implant. As no healing abutment was supplied, a silicone impression plug was placed, and the patient was referred back to Dr. Salehi for re-restoration with Nobel conical components.